-

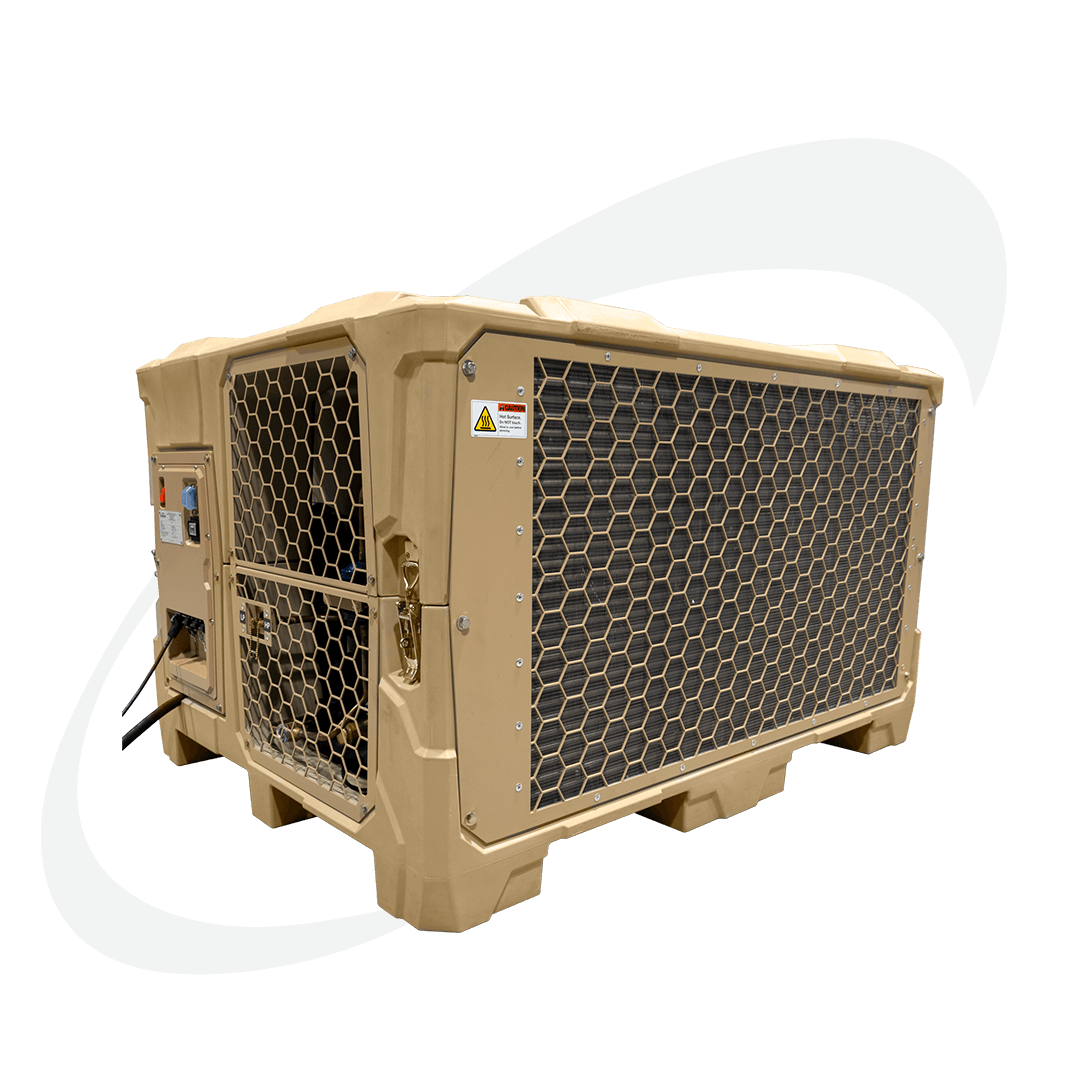

Modular Refrigeration Unit (MRU)

-

Quadcon Refrigerated Container System (QRCS)

-

TriCon Refrigerated Container System (TRCS)

Refrigeration

Modular Refrigeration Unit (MRU)

Tested to U.S. Military Standard 810 – Official Modular Refrigeration Unit used by the U.S. Military

- Designed for high ambient temperatures and desert conditions

- Designed for maintenance or repair with common tools from standard military tool kits

- Mean Time Between Failure (MTBF) rate of 5,202 hours

- 20-year storage life without performance degradation

- Designed for maintenance or repair with common tools from standard military tool kits

- Straightforward, intuitive control panel

- Integrated LCD that simplifies temperature and defrost settings

- 18 LED status indicators and nine jumpers located on the PCB allow user override of sensors and relays

- Wire harnesses are straightforward plug and play

- Brazing, soldering or wire splicing never required

| Physical | ||

|---|---|---|

| Height | 21.4 inches | 54.3 cm |

| Width | 36.8 inches | 93.3 cm |

| Depth | 38 inches | 96.5 cm |

| Weight | 350 lbs | 158.8 kg |

| Electrical Power | ||

|---|---|---|

| MRU-TQ1-404 | 120 VAC, single-phase, 60Hz | |

| MRU-TQ3-404 | 208 VAC, 3-phase, 50/60 Hz Y Connection w/Neutral | |

| Cooling Capacity | ||

|---|---|---|

| MRU-TQ1-404 | 2,800 BTU/hr (820 W) at 0°F/100°F | 6,600 Btu/hr (1,933 W) at 35°F/100°F |

| MRU-TQ3-404 | 4,100 Btu/hr (1,200 W) at 0°F/100°F | 9,750 Btu/hr (2,857 W) at 35°F/100°F |

| Refrigerant | R-404A | 6 lbs 8 oz |

| Set Up Time – The MRU can be installed in less than 30 minutes by two personnel and is operable by a soldier outfitted in all levels of Mission Oriented Protective Posture (MOPP) equipment. The MRU requires less than 90 minutes Mean Time To Repair (MTTR) including evacuation and recharging using standard, commercial support and test equipment. |

|---|

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

Container

Quadcon Refrigerated Container System (QRCS)

Mainstream’s Quadcon Refrigerated Container System (QRCS) is approved by the United Sates Marine Corps (USMC). QRCS is a six-foot ten-inch by eight-foot by four-foot nine-inch (6’10” X 8’ X 4’9”) insulated container with Mainstream’s Modular Refrigeration Unit (MRU) that is powered by an external power source and capable of storing and transporting temperature sensitive cargo. Our MRU maintains the insulated container at freezer or refrigerator temperature ranges in ambient temperatures ranging from -25 to +125°F. Mainstream’s QRCS is certified by NSF International to satisfy sanitary requirements of NSF ANSI 7 Standard for Commercial Refrigerators and Freezers. It is ISO 1496-2 tested and CSC approved. The QRCS operates with 208 VAC, 50/60 Hz, three-phase power input or 120 VAC, 60 Hz, single-phase power.

Tested to U.S. Military Standard 810

Official Modular Refrigeration Unit approved USMC

- Electrically Powered RU with Full-Width Double Door

- Verified to Meet MIL PRF 32335 Requirements

- ISO Tested and CSC Approved

- NSF/ANSI Standard 7 Certified

- High Efficiency with Energy Saver Option

- MTBF 5,022 hrs.

- 20 Year Storage

QRCS/MRU Value-Added Features

Designed for Military Environment

The MRU was designed for the harsh military environment. The unit has been tested to MIL STD 810G (e.g., salt-fog, humidity, sand-dust, solar, ice & freezing rain, blowing rain and watertightness, EMI [RE102 and CE102], high and low temperature operation & storage, ground mobility, rail impact and transit drop).

Improved Air Flow and Air Circulation

Air is drawn into the evaporator so condensation is not sprayed onto the food inside the container. The conditioned air circulates from the evaporator compartment to provide more uniform air flow distribution and prevent air blockage.

Total Unit Modularity

Every component can be replaced with common tools. Tube brazing or wire splicing is never required.

System Redundancy

Component redundancy allows the MRU to operate even if a condenser fan, evaporator fan, fan capacitor or heater fails. Extra terminals are available on the relays if a contact pits and fails.

Energy Saver Option

In freezer mode, an energy saver selection switch automatically operates the MRU longer during cooler periods of the day, such as the evening, to reduce power consumption.

Circuit Breakers

The MRU uses re-settable circuit breakers. There are no fusible links or fuses.

| Physical | ||

|---|---|---|

| Size | 82″H X 96″L X 57″W | |

| Doors | full-width double door | |

| Power Connector | MS90556-C-32412P | |

| Maximum Gross Weight | 11,900 lbs. | |

| Tare Weight | 2,673 lbs. | |

| Payload Capacity | 8,745 lbs. | |

| Internal Volume | 155 cu. ft. | |

| Operating Temperature Range | -25 to 125°F | |

| Storage Temperature Range | -50 to 160°F | |

| Minimum Circuit Ampacity | 15amps at 208VAC 50/6 0 Hz | |

| Requires Y connection w /neutral | ||

| Refrigerant Charge | 6.5 lbs. R-404A | |

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

Container

TriCon Refrigerated Container System (TRCS)

Mainstream’s Tricon Refrigerated Container System (TRCS) is the official TRCS used by the U.S. Armed Forces and is the only TRCS verified to meet MIL-PRF-32335. TRCS is an eight-foot by eight-foot by six-foot six-inch (8′ X 8′ X 6′ 6″) insulated container with Mainstream’s Modular Refrigeration Unit (MRU) that is powered by an external power source and capable of storing and transporting temperature sensitive cargo. Our MRU maintains the insulated container at freezer or refrigerator temperature ranges in ambient temperatures ranging from -25 to +125°F. Mainstream’s TRCS is certified by NSF International to satisfy sanitary requirements of NSF/ANSI 7 Standard for Commercial Refrigerators and Freezers. It is ISO 1496-2 tested and CSC approved. The Type III TRCS variant is equipped with interior shelving units with a 600 lbs.-per-shelf capacity and both interior and exterior lighting. The TRCS operates with 208 VAC, 50/60 Hz, three-phase power input.

Tested to U.S. Military Standard 810

Official Modular Refrigeration Unit used by the U.S. Military

- Type I – Electrically Powered RU with Full-Width Double Door

- Type III – Electrically Powered RU with Single-Man Door

- Verified to Meet MIL-PRF-32335 Requirements

- ISO Tested and CSC Approved

- NSF/ANSI Standard 7 Certified

- High Efficiency with Energy Saver Option

- MTBF 5,022 hrs.

- 20 Year Storage

- Portable Exterior Lighting System (PELS)

Standard on Type III, Optional on Type I

TRCS/MRU Value-Added Features

Designed for Military Environment

The MRU was designed for the harsh military environment. The unit has been tested to MIL-STD-810G (e.g., salt-fog, humidity, sand-dust, solar, ice & freezing rain, blowing rain and watertightness, EMI [RE102 and CE102], high and low temperature operation & storage, ground mobility, rail impact and transit drop).

Improved Air Flow and Air Circulation

Air is drawn into the evaporator so condensation is not sprayed onto the food inside the container. The conditioned air circulates radially from the evaporator compartment to provide more uniform air flow distribution and prevent air blockage.

Total Unit Modularity

Every component can be replaced with common tools. Tube brazing or wire splicing is never required.

NSF Food Grade Shelving Units

The TRCS can be outfitted with NSF certified removable stainless steel shelving units consisting of five 22″ wide shelves spanning the length on each side of the container (standard on Type III, optional on Type I).

PELS Lighting System

Available with an approved Portable Exterior Light System (PELS) with magnetic mounting bracket for attachment anywhere on the exterior of the TRCS (standard on Type III, optional on Type I).

Interior Lights

Available with an approved Interior (White and Black-out) LED lighting system (standard on Type III).

System Redundancy

Component redundancy allows the MRU to operate even if a condensor fan, evaporator fan, fan capacitor or heater fails. Extra terminals are available on the relays if a contact pits and fails.

Energy Saver Option

In freezer mode, an energy saver selection switch automatically operates the MRU longer during cooler periods of the day, such as the evening, to reduce power consumption.

Circuit Breakers

The MRU uses re-settable circuit breakers; there are no fusible links or fuses.

| Physical | Type I | Type III | ||

|---|---|---|---|---|

| Size | 96″ x 77.5″ x 96″ | 96″ x 77.5″ x 96″ | ||

| Doors | full-width double door | single-man door | ||

| PELS Light | Optional | Included/Standard | ||

| Removable Stainless Steel Shelves | Optional | (5) 22″ wide shelves included/Standard | ||

| Power Connector | MS90556-C-32412P | MS90558-C-32412P | ||

| Maximum Gross Weight | 26,460 lb | 26,460 lb | ||

| Tare Weight | 3,880 lb | 4,630 lb | ||

| Payload Capacity | 22,580 lb | 21,830 lb | ||

| Operating Temperature Range | -25 to 125°F | -25 to 125°F | ||

| Storage Temperature Range | -50 to 160°F | -50 to 160°F | ||

| Minimum Circuit Ampacity | 15 amps at 208 VAC 50/60 Hz Requires Y connection w/neutral | 15 amps at 208 VAC 50/60 Hz Requires Y connection w/neutral | ||

| Refrigerant Charge | 6.5 lbs R-404A | 6.5 lbs R-404A | ||

| NSN (National Stock Number) | ||

|---|---|---|

| Type I | 8145-01-598-4828 | |

| Type III | 8145-01-598-4829 | |

| Type III PELS | 6230-01-630-7370 | |

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

HVAC

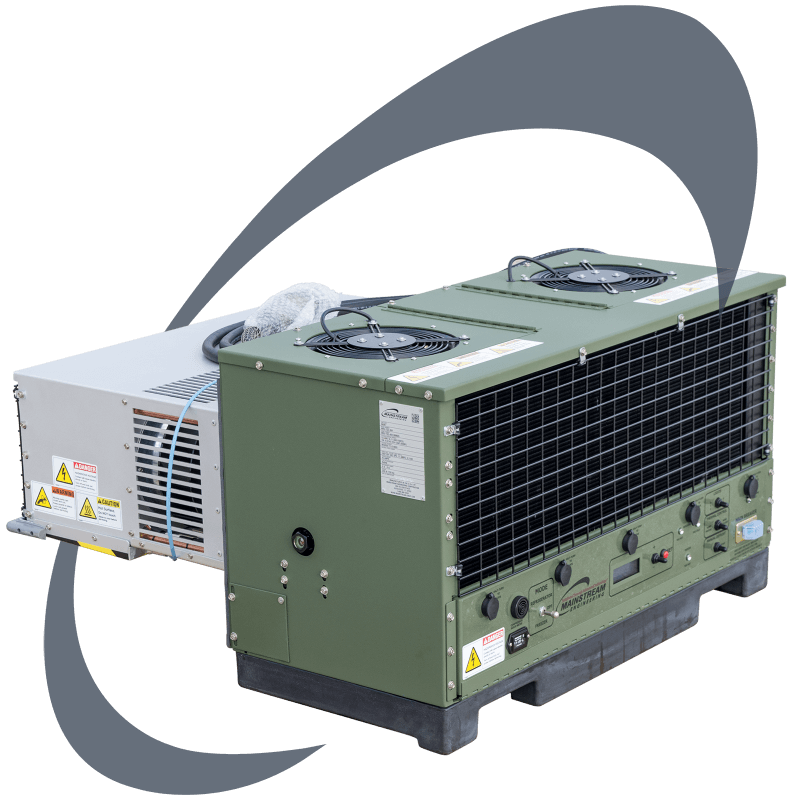

Ruggedized Environmental Control Unit (RECU)

Mainstream’s 5-tonR RECU is the latest in ultra-efficient, military-ready, ducted, unitary, heat pump systems. It provides heating, ventilation, and air conditioning to USAF BEAR Base shelters. The RECU is compatible with NBC filter/blower equipment and is certified to operate with Collective Protection (ColPro) equipment in a chemical, biological, radiological, and nuclear (CBRN) environment. The RECU also includes compressor soft-start technology and microprocessor-based embedded diagnostics/prognostics. These units were designed to replace the FDECU, LECU, and the IECU while improving performance, reducing weight, simplifying maintenance, and increasing reliability. Optional wye ducts are available, allowing one RECU to cool two shelters.

| Part # | RECU60K134 |

| On GSA Contract | Yes |

| USAF Part # | E2CU60K3208 |

| NSN-USAF | Pending |

| L x W x H | 61″ x 42″ x 38-1/4″ |

| Weight | 647 lbs |

| Service Life | 25 years |

| Recommended Inspection Interval | 36 months |

| Duct Diameter | 16″ |

| Duct Length | 8′ |

| Noise | 79 dBA |

| Input Power | 208/230 VAC, 3 phase, 50/60 Hz |

| RECU Breaker Rating | 50 A |

| Cable | 25′ SOOW |

| Connector | Class L MS90556C32412P |

| Evaporator Air Flow | 2000 scfm @ 1 in.H2O |

| Soft Start | Yes |

| Type | R-134a/HFO Compatible |

| Charge | 12 lbs |

| Cooling (@ 125/90/75°F) | 68,000 Btu/hr |

| Heating (Electric) | 35,600 Btu/hr |

| Heating (Heat Pump) | Yes |

| Digital Remote Thermostat | Yes |

| Digital Diagnostics and Prognostics | Yes |

| Digital Display | Yes |

| Microgrid Compatible | Yes |

| Cooling | 50°F to 125°F |

| Heating | -25°F to 75°F |

| 463L Pallet Transport | Up to 6 Units |

| Tricon Transport | Up to 4 Units |

| BEAR Compatible | Yes |

| Collective Protection (ColPro) Certified | Yes |

| NBC Filter/Blower Equipmnet Compatible | Yes |

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

HVAC

Improved Environmental Control Unit (IECU)

- Designed for Military Environment

- Simple and intuitive control panel

- No Training required for basic operation

- Software upgradable PCB controller with battle-short capability

- Removable remote provides for control at a convenient location

- Designed for maintenance or repair with common hand tools from standard military tool kit.

- Diagnostics Port allows complete troubleshooting with only a multimeter

- Embedded diagnostics and 16 board-mounted LED indicators simplify maintenance

- Plug and play modular components

- Brazing/soldering not required during any maintenance procedure

- All refrigerant components have threaded O-ring fittings that can be replaced with simple hand tools

- Soft start device helps protect tactical power grids by limiting in rush current at start up.

- EMI conducted and radiated emissions tested to MIL-461F

- Designed for 20 year storage life

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

Converter

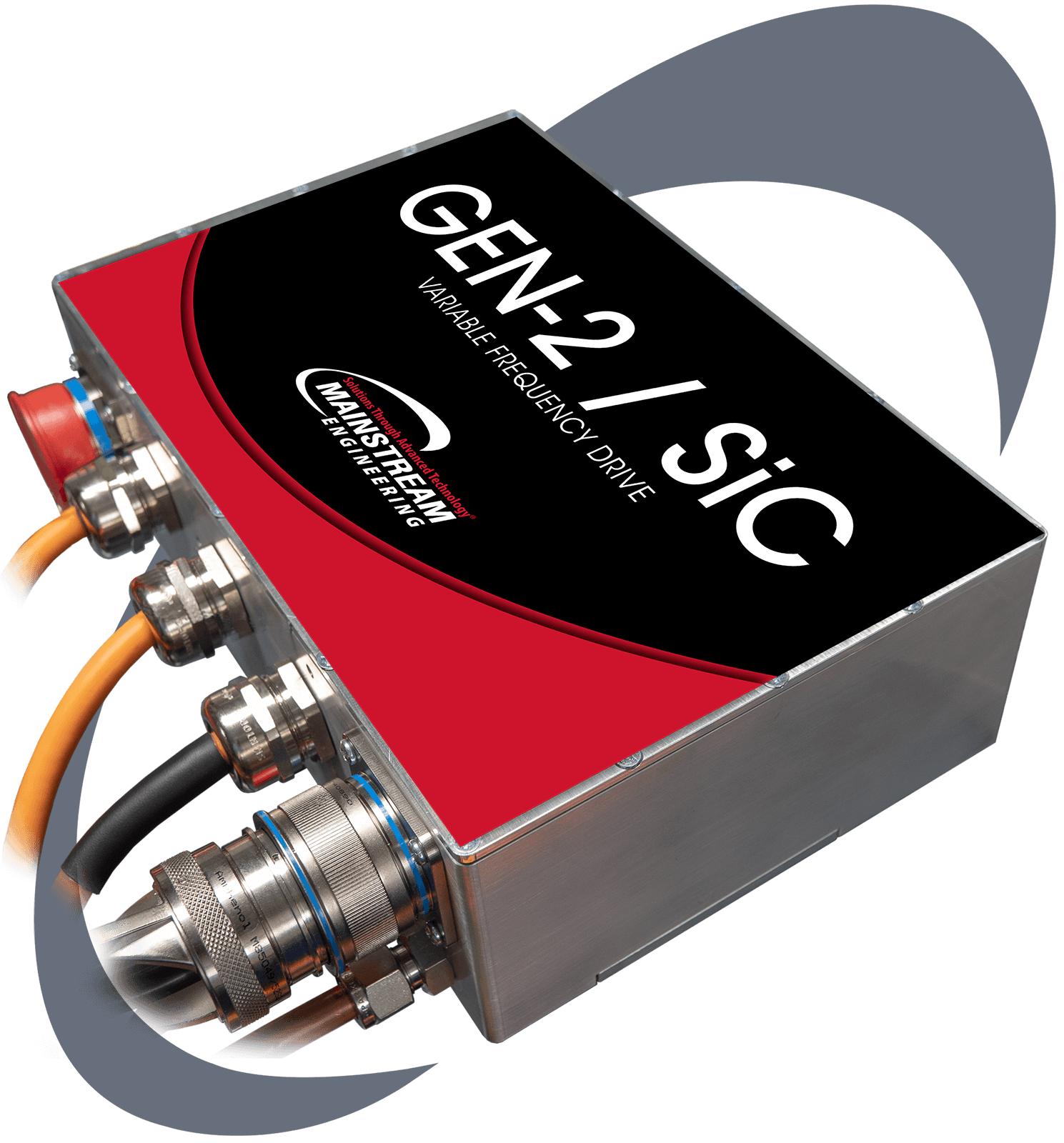

25kW SiC-based OPTI Drive

Mainstream designed, built and tested a 25 kW continuous (35 kW peak), 105 °C liquid cooled, wide-bandgap (WBG) three-phase motor drive. This motor drive is based on a custom SiC module. The motor drive is 99% efficient, weighs only 11.5 lbs, and has dimensions of 11″ x 7″ x 3.5″. Installation into the end application vehicle is also simplified because all electrical and fluid connections are located on the same enclosure face.

Available Soon...

Available Soon...

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

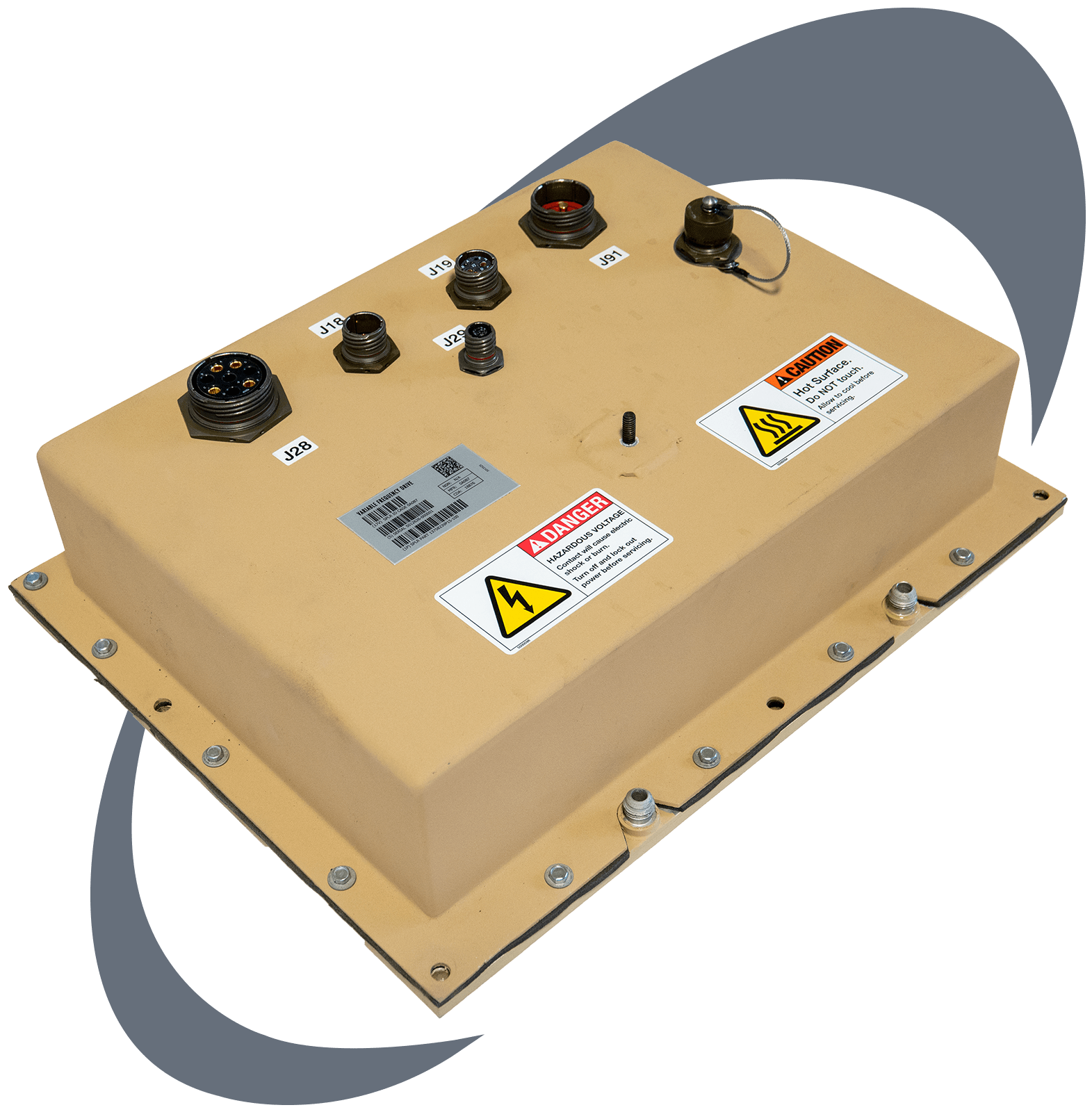

Converter

10kW IGBT-based Opti Drive

Mainstream’s variable frequency drive is a liquid cooled motor drive with an integrated active PFC rectifier for meeting the strict requirements of MIL-STD 461. It can be powered by a 208/230 Vac, 50/60 Hz source (such as the AC grid, a generator, or a tactical microgrid) or modified to operate from a DC source. The motor drive can be used with fluid inlet temperatures from -40° to 70°C and drive AC induction motors or AC permanent magnet synchronous motors using advanced sensorless field-oriented control.

| Dimensions (L x W x H) | 17.5 x 13.5 x 4.25 | Inches | ||

| Weight | 31 | lbs | ||

| AC Input Voltage | 183 | 208 | 240 | Vline-line rms |

| AC Input Frequency | 45 | 50/60 | 66 | Hz |

| Line Voltage Unbalance | -5% | 0 | 5% | |

| Input Current | 25 | Arms per line | ||

| Inrush Current | < 25 | Apeak per line | ||

| Input Power Factor (DPF) | 0.99 | Displacement power factor | ||

| Input Power Factor (HPF) | 0.99 | Harmonic power factor | ||

| AC Output Voltage | 0 | 230 | Vline-line rms | |

| AC Output Frequency | 0 | 1000 | Hz | |

| AC Output Current | 0 | 25 | Arms per line | |

| Output Voltage dV/dt | 2.5 | kV/µs |

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

Converter

Satellite Space Converter

Available Soon...

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

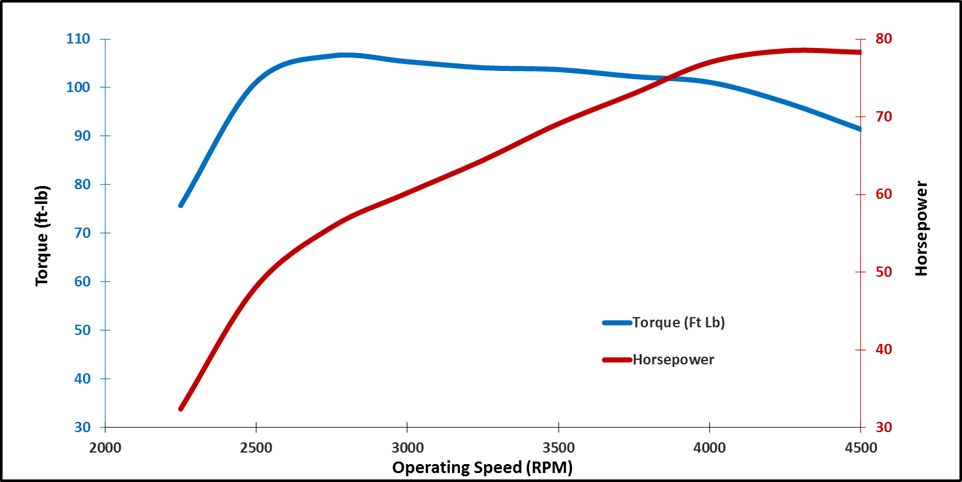

Engine

Advanced Modular Diesel 45

AMD45 (Advanced Modular Diesel 3-Cylinder, 1.25 L, Turbodiesel 75 Horsepower (56 kW)

The AMD45 Turbodiesel was developed with automotive design principles coupled with durability enhancements for demanding military and industrial applications. It is well suited for small high performance transport vehicles (ATVs & riverine craft), generator/APU applications, hydraulic power units, and pumps.

- Fuel efficient high-pressure common rail injection

- Advanced electronic engine controls

- Quiet multi-pulse combustion

- Wide, smooth powerband

- Lightweight aluminum engine

- Silent self-adjusting zero lash valvetrain

- Low maintenance electric water pump

- Designed for Jet A, JP-5, JP-8, and diesel fuels

- Front-mount PTO/ISA drive interface at crankshaft speed

Benefits

- Automotive turbocharged diesel performance is combined with industrial diesel durability

- Lightweight all-aluminum design makes this the lightest engine in its class

- Reduced noise and exhaust emissions with electronically controlled multi-pulse combustion

- Fuel efficient high-pressure common rail fuel injection

- Multi-fuel platform is compatible with diesel, Jet-A, JP-5 and JP-8 fuels

- Broad powerband, delivered through high rpm operation

- Low maintenance design, with no adjustable mechanical devices

- Long life durability, designed for 8000 hours MTBEFF in stationary use applications

- Power take off (PTO) can drive accessories of up to 40hp at 4500 rpm from the crankshaft end opposite the vehicle drive system

- Hybrid ready PTO can be driven up to 40 hp, which is directly added to available vehicle power

- Glow plugs are centrally located in the combustion chamber for quick cold weather starts

- Coolant is circulated by an electric water pump for easy maintenance and excellent temperature control

- Remote mountable water pump increases flexibility in vehicle packaging

- Compact architecture has fully integrated components to reduce size

- Contains a gear-driven balancer shaft for smooth operation with no maintenance

Operating Hours: Monday – Friday 8:00 a.m. – 5:00 p.m. EST

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550

Radar

Tactical Mobile Radar Thermal Management System

Mainstream’s OPTI Variable-Speed Pump

Mainstream’s OPTI Variable-Frequency Drive

Mainstream’s OPTI Microchannel Radiator

Mainstream’s OPTI Active Accumulator

Fully Operational on rotating platform (30 rpm)

Designed for base and growth modes

Operates in ambient temperatures between -40°C and +48°C

Operates in all military conditions – designed IAW MIL-STD-810 environmental requirements

Designed to the electromagnetic interference requirements of MIL-STD-461, including: CS101, CE102, CS114, CS115, CS116, CS118, RE102, and RS103

Operating Hours: Monday – Friday 8:00 a.m. – 5:00 p.m. EST

Contact: Send us an email – militarysales@mainstream-engr.com

Phone: 321-631-3550