01

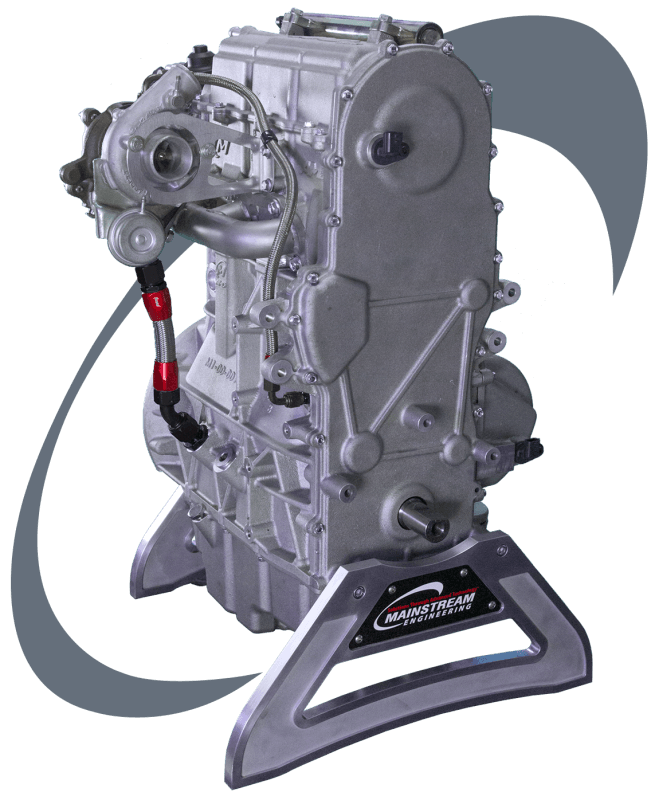

Diesel Engine

AMD Engines

Mainstream designs and manufactures purpose-built engines for demanding, niche applications such as military generators, unmanned aerial vehicles, alternative fuel generators, and high-efficiency vehicles. We also design and build custom integrated starter alternators and power conditioning electronics for generator and hybrid-drive applications. Example engine development programs include ultra-lightweight three-cylinder turbocharged diesel engine for military APUs and vehicles, hybrid-electric turbocharger for waste heat harvesting and transient lag reduction, compact 500-W diesel generator to power railway track monitoring equipment, biogas-tolerant engine-generator for anaerobic digesters, and cavitation-enhancing fuel injector nozzle for small-displacement diesel engines.

Contact: Send us an email – info@mainstream-engr.com

Phone: 321-631-3550

02

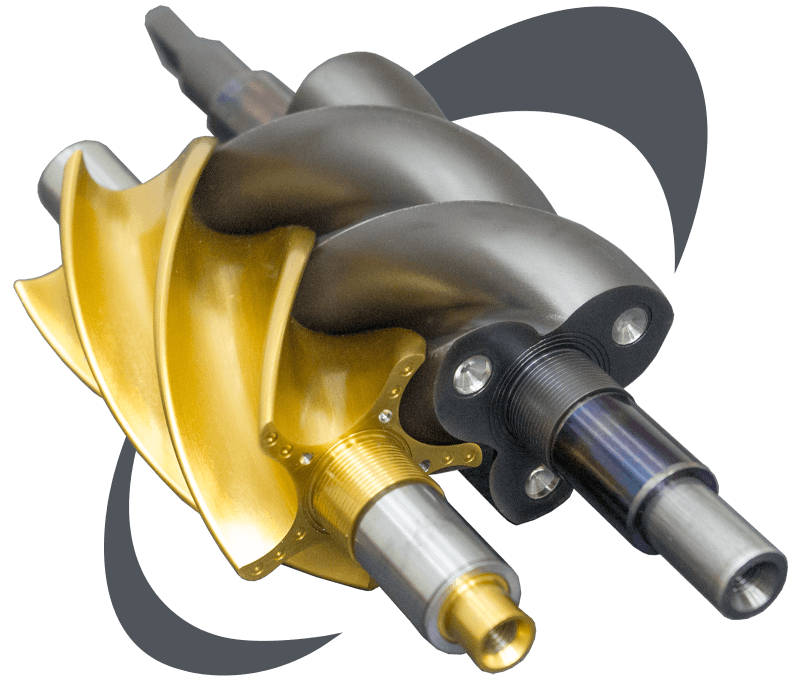

Turbomachines

Compressors and Turbines

- Compressors – Mainstream develops custom screw, reciprocating, centrifugal, and rotary vane compressors for various applications, including cooling systems for high energy lasers used in directed energy weapons and thermal management systems for space-based applications. One of our compressors has even operated on the International Space Station as part of an oil-less refrigerated centrifuge.

- Turbines – Mainstream develops custom high-speed axial and radial flow turbines for power generation applications. Additionally, Mainstream has developed an internally-located 60 kW ram air turbine for radar jamming applications (EA-18G advanced airborne electronic attack aircraft) as well as waste heat recovery turbines for inorganic Rankine cycle systems.

Contact: Send us an email – info@mainstream-engr.com

Phone: 321-631-3550

03

Robotic 3D Printer

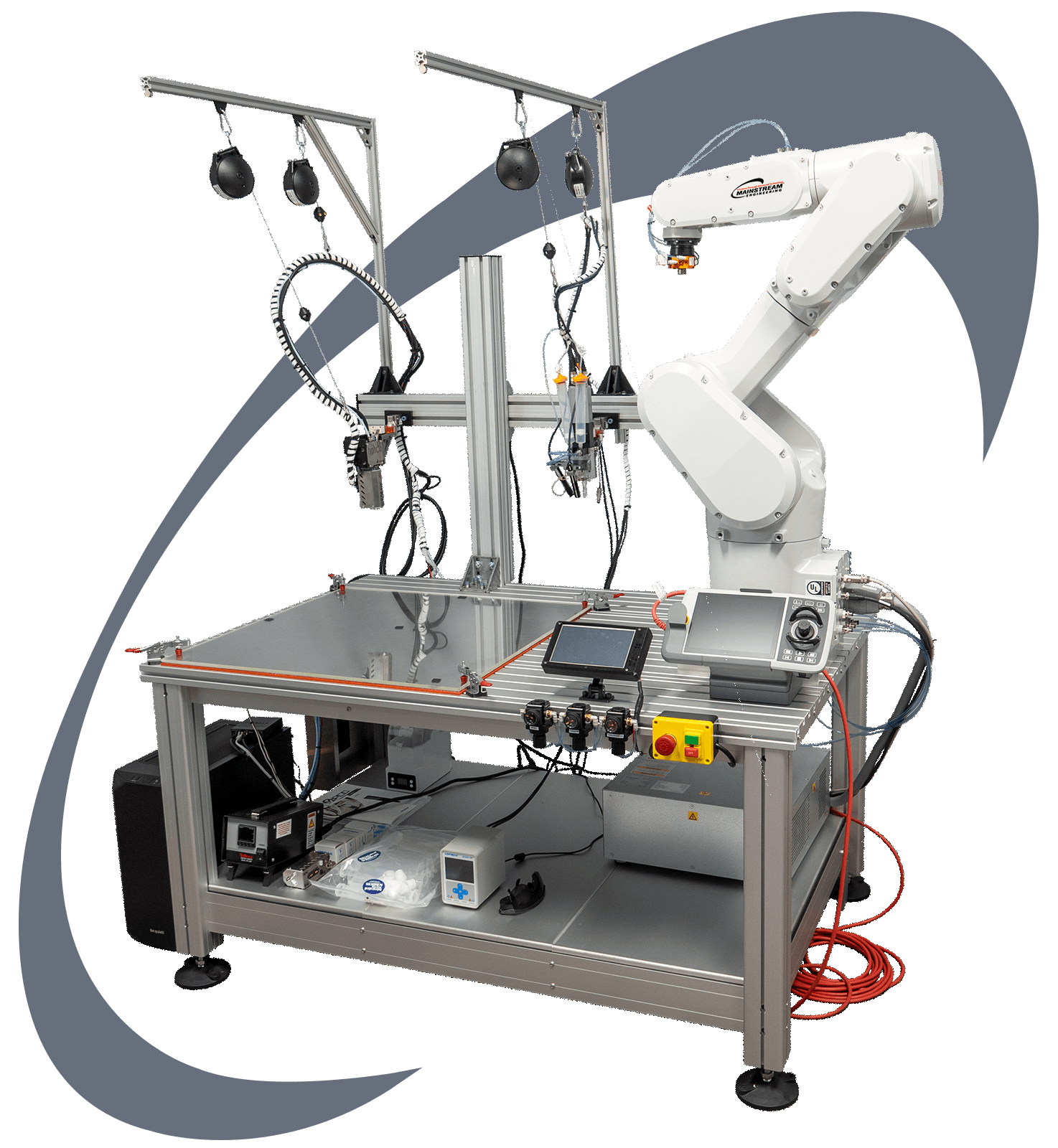

Multi-Material Robotic Additive Manufacturing (MRAM)

Mainstream has developed a multi-material robotic additive manufacturing (MRAM) system for robotic, thermal, electrical, and materials R&D. This custom robotic-arm-based 3D printer uses a six-Degree-of-Freedom (DoF) robotic arm to print on a 30″x30″ heated print bed. The inclusion of a 6-DoF robotic arm instead of a conventional 3-DoF gantry enables multi-axis movements and material deposition on curved surfaces. Moreover, a tool changer attached to the robotic arm easily integrates various tools into each print. Example tools include an extruder for printing, a pick-and-place tool for adding components mid-print, and a milling spindle for post-process machining. Currently, the MRAM features a high-throughput Fused Deposition Modeling (FDM) extruder capable of extruding high-temperature thermoplastics and a dual-chamber Direct Ink Write (DIW) resin extruder with an integrated UV curing system.

These integrated extruders allow us to print nearly any material of interest, including high-performance thermoplastics, highly-filled thermosets, conductive inks, and ceramic slurries with various fillers, additives, and modifiers. Further, they enable secondary operations such as pick-and-place components mid-print and post-process machining.

Operating Hours: Monday – Friday 8:00 a.m. – 5:00 p.m. EST

Contact: Send us an email – info@mainstream-engr.com

Phone: 321-631-3550

Meet our Mechanical Engineer Team

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo, when an unknown printer took a galley.