In-Situ Fabrication of Spacecraft Heat Shields

ROCKLEDGE, FL — June 14th, 2021 — Mainstream Engineering Corporation has been awarded a contract from NASA for In-Situ Fabrication of Spacecraft Thermal Protection Systems.

Current state-of-the-art methods for the fabrication of thermal protection systems (TPS) for spacecraft are costly, labor-intensive, and limited to on-Earth production. To address these shortcomings, Mainstream, in collaboration with Virginia Tech is developing additive manufacturing (AM) system for the in-situ fabrication of a high-heat-flux ablative TPS.

The Spacecraft Thermal protection system Additive Manufacturing (STAM) system utilizes a robotic arm that is programmed to allow for heat sink material deposition on any complex geometry of a spacecraft. The STAM system can autonomously fabricate a full-scale conformal TPS directly onto the spacecraft exterior.

Improving heat shield performance and lowering cost is critical to future missions, including manned missions to the Moon and Mars. In addition, hypersonic vehicles experience high heat fluxes and temperatures associated with hypersonic flight. These vehicles would also benefit from an improved thermal protection system.

About Mainstream Engineering Corporation

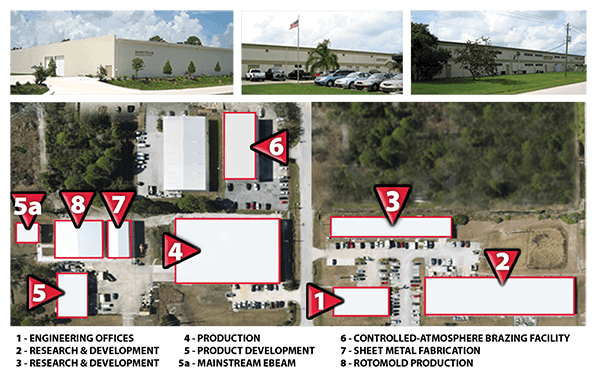

Mainstream Engineering Corporation is a 35-year-old Brevard County, Florida manufacturer with a history of leading-edge research and development that has resulted in advanced cost-competitive products, which are made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced R&D into high-quality, environmentally safe, green, commercial products using lean manufacturing techniques. Areas of research include thermal control, energy conversion, power electronics, biomass conversion, chemical technology, and materials science. All Mainstream products are made in the USA.

Current state-of-the-art methods for the fabrication of thermal protection systems (TPS) for spacecraft are costly, labor-intensive, and limited to on-Earth production. To address these shortcomings, Mainstream, in collaboration with Virginia Tech is developing additive manufacturing (AM) system for the in-situ fabrication of a high-heat-flux ablative TPS.

The Spacecraft Thermal protection system Additive Manufacturing (STAM) system utilizes a robotic arm that is programmed to allow for heat sink material deposition on any complex geometry of a spacecraft. The STAM system can autonomously fabricate a full-scale conformal TPS directly onto the spacecraft exterior.

Improving heat shield performance and lowering cost is critical to future missions, including manned missions to the Moon and Mars. In addition, hypersonic vehicles experience high heat fluxes and temperatures associated with hypersonic flight. These vehicles would also benefit from an improved thermal protection system.

About Mainstream Engineering Corporation

Mainstream Engineering Corporation is a 35-year-old Brevard County, Florida manufacturer with a history of leading-edge research and development that has resulted in advanced cost-competitive products, which are made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced R&D into high-quality, environmentally safe, green, commercial products using lean manufacturing techniques. Areas of research include thermal control, energy conversion, power electronics, biomass conversion, chemical technology, and materials science. All Mainstream products are made in the USA.