Mainstream Engineering Awarded Contract from the Department of Energy to Improve Quality Control for Fuel Cell Membrane Manufacturing

ROCKLEDGE, FL – September 4th, 2015 – Mainstream Engineering Corporation, a 29-year-old Brevard County research and manufacturing company, has been awarded a grant from the Department of Energy to develop an in-line detector for monitoring the quality of fuel cell membranes on the manufacturing line.

Modern fuel cells have been in development since the 1960s and stand on the cusp of commercialization; however, market penetration as a power source for cars or consumer products has been limited because of the high costs of manufacturing the devices. The objective of Mainstream’s program is to reduce manufacturing costs through early detection of defects in the fuel cell membrane component, which contributes up to 45% of the total cost of the device. These defects are often not discovered until after a precious metal catalyst has been irreversibly applied to the membrane, leading to costly scrap material and downtime of the membrane extrusion or casting process.

Mainstream Engineering has been awarded a Phase I SBIR grant to develop a low-cost detector for continuous, autonomous analysis of membrane thickness, composition, and defects for polymer electrolyte membrane (PEM) fuel cell membranes. The proposed inspection technique samples every location on the roll of material so defects can be removed before assembly into complete cells. This 100% inspection strategy promises to significantly reduce manufacturing costs and improve process efficiency.

About Mainstream Engineering

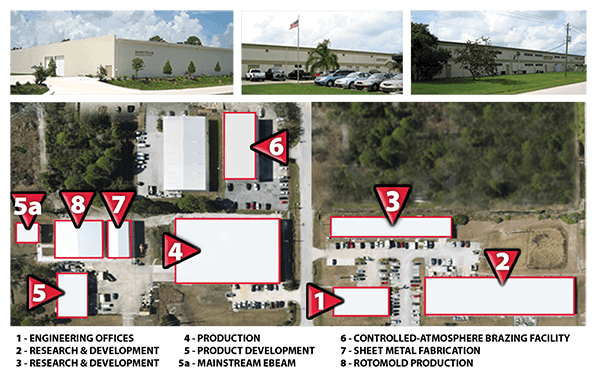

Mainstream Engineering Corporation is a solutions-oriented research, development and manufacturing small business with a history of leading-edge research and development that has resulted in advanced, lean-manufacturing, cost-competitive products, which are all made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced thermal control, energy storage and energy conversion technologies into high-quality, cost-effective, environmentally-safe green, American made products. Products include lightweight diesel/JP8-fueled engines (including generators and hybrid vehicle drive trains), advanced thermal control units, advanced biomass conversion technologies, refrigerators/freezers for shipping containers, fuel cells, advanced batteries, advanced materials and the QwikProduct™ line of heating, ventilation, air conditioning, and refrigeration (HVAC/R) products. Areas of advanced research include thermal control, energy conversion, engine and emissions research, turbomachinery, chemical technology, and materials science.

Modern fuel cells have been in development since the 1960s and stand on the cusp of commercialization; however, market penetration as a power source for cars or consumer products has been limited because of the high costs of manufacturing the devices. The objective of Mainstream’s program is to reduce manufacturing costs through early detection of defects in the fuel cell membrane component, which contributes up to 45% of the total cost of the device. These defects are often not discovered until after a precious metal catalyst has been irreversibly applied to the membrane, leading to costly scrap material and downtime of the membrane extrusion or casting process.

Mainstream Engineering has been awarded a Phase I SBIR grant to develop a low-cost detector for continuous, autonomous analysis of membrane thickness, composition, and defects for polymer electrolyte membrane (PEM) fuel cell membranes. The proposed inspection technique samples every location on the roll of material so defects can be removed before assembly into complete cells. This 100% inspection strategy promises to significantly reduce manufacturing costs and improve process efficiency.

About Mainstream Engineering

Mainstream Engineering Corporation is a solutions-oriented research, development and manufacturing small business with a history of leading-edge research and development that has resulted in advanced, lean-manufacturing, cost-competitive products, which are all made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced thermal control, energy storage and energy conversion technologies into high-quality, cost-effective, environmentally-safe green, American made products. Products include lightweight diesel/JP8-fueled engines (including generators and hybrid vehicle drive trains), advanced thermal control units, advanced biomass conversion technologies, refrigerators/freezers for shipping containers, fuel cells, advanced batteries, advanced materials and the QwikProduct™ line of heating, ventilation, air conditioning, and refrigeration (HVAC/R) products. Areas of advanced research include thermal control, energy conversion, engine and emissions research, turbomachinery, chemical technology, and materials science.