Mainstream Engineering Awarded Contract from the MDA for Developing a Revolutionary New Method for Screening of Capacitors

ROCKLEDGE, FL – August 18th, 2015 – Mainstream Engineering Corporation, a 29-year-old Brevard County research and manufacturing company, has been awarded a contract from the Missile Defense Agency (MDA) to develop an advanced method to analyze and screen for potential failures of capacitors.

Over 95% of the multilayer ceramic capacitors manufactured worldwide use base metal electrode (BME) technologies. These capacitors are one of the key components in a wide array of modern electronic devices from cell phones to automotive electronics. Over the last 20 years, significant improvements have been made in the performance and reliability of BME capacitors, making them more competitive for a wide range of applications.

To increase the implementation of BME capacitors in high-reliability platforms, a robust, reliable, and non-destructive screening method is necessary for evaluating BME multi-layer ceramic capacitors. This screening method is needed for both in-process steps and the finished device to increase the yields of high-reliability capacitors and prevent early catastrophic failure. In current methods, the partially complete or final devices have to be destroyed to check for the potential for failure.

To achieve the reliability of these devices in the military and aerospace applications, Mainstream is developing a robust, sensitive, and non-destructive method of evaluating and identifying potential for failure modes in the component materials and the assembled BME capacitors. By enabling 100% inspection of all capacitors coming off an assembly line, this provides a reliable analysis of the dielectric layers, highlighting adverse effects to device lifetime.

Implementation of this technology in fabrication assembly lines will have an immediate and lasting effect on the reliability and performance of BME capacitors. In addition, yields will be increased and costs will be lowered by finding early failures in production materials and processes.

About Mainstream Engineering

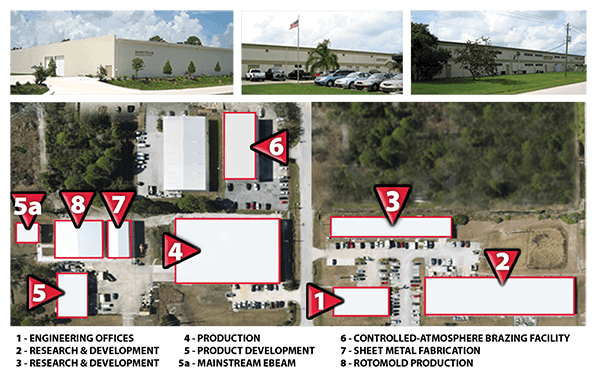

Mainstream Engineering Corporation is a solutions-oriented research, development, and manufacturing small business with a history of leading-edge research and development that has resulted in advanced, lean-manufacturing, cost-competitive products, which are all made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced thermal control, energy storage, and energy conversion technologies into high-quality, cost-effective, environmentally-safe green, American-made products. Products include lightweight diesel/JP8-fueled engines (including generators and hybrid vehicle drive trains), advanced thermal control units, advanced biomass conversion technologies, refrigerators/freezers for shipping containers, fuel cells, advanced batteries, advanced materials, and the QwikProduct™ line of heating, ventilation, air conditioning, and refrigeration (HVAC/R) products. Areas of advanced research include thermal control, energy conversion, engine and emissions research, turbomachinery, chemical technology, and materials science.

Over 95% of the multilayer ceramic capacitors manufactured worldwide use base metal electrode (BME) technologies. These capacitors are one of the key components in a wide array of modern electronic devices from cell phones to automotive electronics. Over the last 20 years, significant improvements have been made in the performance and reliability of BME capacitors, making them more competitive for a wide range of applications.

To increase the implementation of BME capacitors in high-reliability platforms, a robust, reliable, and non-destructive screening method is necessary for evaluating BME multi-layer ceramic capacitors. This screening method is needed for both in-process steps and the finished device to increase the yields of high-reliability capacitors and prevent early catastrophic failure. In current methods, the partially complete or final devices have to be destroyed to check for the potential for failure.

To achieve the reliability of these devices in the military and aerospace applications, Mainstream is developing a robust, sensitive, and non-destructive method of evaluating and identifying potential for failure modes in the component materials and the assembled BME capacitors. By enabling 100% inspection of all capacitors coming off an assembly line, this provides a reliable analysis of the dielectric layers, highlighting adverse effects to device lifetime.

Implementation of this technology in fabrication assembly lines will have an immediate and lasting effect on the reliability and performance of BME capacitors. In addition, yields will be increased and costs will be lowered by finding early failures in production materials and processes.

About Mainstream Engineering

Mainstream Engineering Corporation is a solutions-oriented research, development, and manufacturing small business with a history of leading-edge research and development that has resulted in advanced, lean-manufacturing, cost-competitive products, which are all made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced thermal control, energy storage, and energy conversion technologies into high-quality, cost-effective, environmentally-safe green, American-made products. Products include lightweight diesel/JP8-fueled engines (including generators and hybrid vehicle drive trains), advanced thermal control units, advanced biomass conversion technologies, refrigerators/freezers for shipping containers, fuel cells, advanced batteries, advanced materials, and the QwikProduct™ line of heating, ventilation, air conditioning, and refrigeration (HVAC/R) products. Areas of advanced research include thermal control, energy conversion, engine and emissions research, turbomachinery, chemical technology, and materials science.