Mainstream Engineering to Develop a Quality Control System for Electrolyzer Manufacturing

ROCKLEDGE, FL — April 3, 2019 — Mainstream Engineering Corporation has been awarded a contract from the University of Connecticut to develop a quality control system for manufacturing components found in electrolyzers. This work is part of a larger project funded by the Department of Energy to improve the design, manufacturing, and quality control of electrolyzers used to produce hydrogen. The project is one of the 28 projects supporting early-stage hydrogen and fuel cell R&D that was announced by U.S. Secretary of Energy Rick Perry last August.

Electrolyzers use electrical power, potentially from renewable sources, to split water to produce hydrogen for fuel cell vehicles and other industrial uses. There is a critical need to reduce the cost of electrolyzers to enable wide-scale hydrogen production and utilization in the United States—a challenge undertaken by DOE’s H2@Scale initiative.

The most expensive component in the electrolysis cell stack is the membrane electrode assembly, which contains the precious metals platinum and iridium as catalysts. UConn has pioneered a reactive spray deposition technology (RSDT) that reduces the amount of catalyst needed for the membrane electrode assemblies, thereby reducing cost. Engineers at Mainstream have developed an in-line optical scanner for quality control of the RSDT process. This real-time quality control inspection process uses Mainstream’s Mainstream’s Mantis Eye™ scanner technology for in-line quality control of roll-to-roll membrane manufacturing. Improved real-time continuous inspection at manufacturing speeds is required to ensure large amounts of costly scrap are not generated before a process deviation can be detected. Improved real-time inspection will reduce the cost of electrolyzers and help to enable the affordable, wide-scale generation and use of hydrogen as a clean energy carrier.

About Mainstream Engineering Corporation

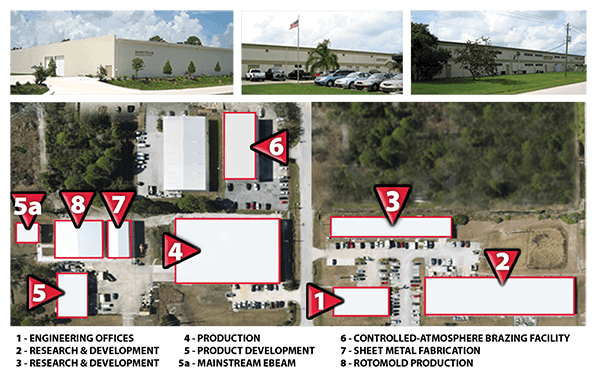

Mainstream Engineering Corporation is a 33-year-old Brevard County, Florida manufacturer with a history of leading-edge research and development that has resulted in advanced cost-competitive products, which are made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced R&D into high-quality, environmentally safe, green, commercial products using lean manufacturing techniques. Areas of research include thermal control, energy conversion, power electronics, biomass conversion, chemical technology, and materials science.

Electrolyzers use electrical power, potentially from renewable sources, to split water to produce hydrogen for fuel cell vehicles and other industrial uses. There is a critical need to reduce the cost of electrolyzers to enable wide-scale hydrogen production and utilization in the United States—a challenge undertaken by DOE’s H2@Scale initiative.

The most expensive component in the electrolysis cell stack is the membrane electrode assembly, which contains the precious metals platinum and iridium as catalysts. UConn has pioneered a reactive spray deposition technology (RSDT) that reduces the amount of catalyst needed for the membrane electrode assemblies, thereby reducing cost. Engineers at Mainstream have developed an in-line optical scanner for quality control of the RSDT process. This real-time quality control inspection process uses Mainstream’s Mainstream’s Mantis Eye™ scanner technology for in-line quality control of roll-to-roll membrane manufacturing. Improved real-time continuous inspection at manufacturing speeds is required to ensure large amounts of costly scrap are not generated before a process deviation can be detected. Improved real-time inspection will reduce the cost of electrolyzers and help to enable the affordable, wide-scale generation and use of hydrogen as a clean energy carrier.

About Mainstream Engineering Corporation

Mainstream Engineering Corporation is a 33-year-old Brevard County, Florida manufacturer with a history of leading-edge research and development that has resulted in advanced cost-competitive products, which are made in the USA. Founded in 1986, Mainstream’s mission is to transition advanced R&D into high-quality, environmentally safe, green, commercial products using lean manufacturing techniques. Areas of research include thermal control, energy conversion, power electronics, biomass conversion, chemical technology, and materials science.